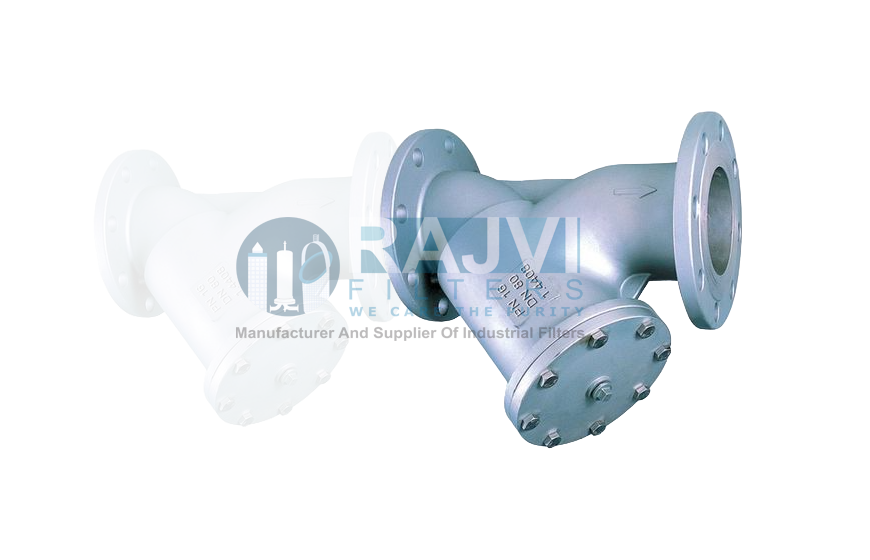

Y type T type Strainer

Y type T type Strainer

Product Description

Y-type and T-type strainers are two common types of filtration devices used in piping systems to remove solid particles and debris from flowing fluids, such as liquids or gases. These strainers help protect downstream equipment, such as pumps, valves, and instruments, from damage or clogging caused by contaminants in the fluid.

Product Details

| MOC | SS316L, SS316, SS304L , SS304, MS, PP , CS , IC |

| Type | T-Type & Y-Type |

| Test Pre. | up to 100 kg/cm2 |

| Filtration Rating | 20 Mesh to 400 Mesh |

| Line Size | 3/4″ NB to 16″ NB |

| Connection Type | BSP (F), NPT (F) Threaded, Flanged 150#, Socket Weld |

| MOC | SS316L, SS316, SS304L , SS304, MS, PP , CS , IC |

| Type | T-Type & Y-Type |

Y-Type Strainer Key Features:

Y-Shaped Design:

The Y configuration optimizes the straining process, allowing for maximum particle capture.

Durable Construction:

Crafted from robust materials, our Y-type strainer is built to withstand harsh operating conditions and ensure a long service life.

Easy Maintenance:

Quick and hassle-free cleaning or replacement of the strainer screen keeps your system running smoothly.

Versatile Applications:

Suitable for a wide range of industries, including petrochemical, water treatment, HVAC, and more.

Various Sizes:

Available in a range of sizes to accommodate different flow rates and pipe diameters.

Efficient Flow:

Minimal pressure drop ensures efficient fluid flow and minimizes energy consumption.

T-Type Strainer Key Features:

T-Shaped Design:

The T configuration provides effective filtration while allowing for easy installation in your pipeline.

Sturdy Construction:

Built to endure harsh environments, our T-type strainer guarantees durability and reliability.

Simple Maintenance:

Straightforward screen cleaning or replacement minimizes downtime and maintenance costs.

Wide Application Range:

Suitable for diverse industries, such as chemical processing, food and beverage, pharmaceuticals, and more.

Various Sizes:

Available in multiple sizes to accommodate different flow rates and pipe sizes.

Low Pressure Drop:

Efficient filtration without compromising fluid flow, saving energy and costs.

Related Products